Conveyor systems are indispensable in manufacturing, logistics, and various industries, offering efficiency and streamlined operations. However, their benefits come with inherent risks that can lead to downtime, injuries, and legal liabilities if not addressed proactively. Understanding these risks and implementing preventative measures can safeguard productivity and safety.

1. Mechanical Failures

Risk: Worn-out components like belts, pulleys, or motors can lead to system breakdowns.

Solution: Regular inspections and maintenance schedules can detect early signs of wear and tear, preventing costly interruptions.

2. Improper Installation

Risk: Poorly installed conveyor systems often result in misalignment, inefficient operation, or frequent breakdowns.

Solution: Always work with qualified professionals to ensure systems are installed correctly and according to manufacturer guidelines.

3. Lack of Operator Training

Risk: Untrained workers may misuse or inadvertently damage conveyor systems, increasing the risk of accidents.

Solution: Provide comprehensive training on operating procedures, safety protocols, and emergency responses.

4. Overloading

Risk: Exceeding a conveyor’s weight limit can strain components, leading to premature failure.

Solution: Adhere to manufacturer-specified load limits and use sensors to monitor load weights in real time.

5. Inadequate Safeguards

Risk: Exposed moving parts can cause serious injuries to workers.

Solution: Install protective guards, emergency stop buttons, and other safety features to minimize the risk of accidents.

6. Slippage and Spillage

Risk: Improper belt tension or inadequate containment can lead to material slipping or spilling, creating hazards and reducing productivity.

Solution: Adjust belt tension regularly and ensure proper containment systems are in place.

7. Poor Maintenance Practices

Risk: Ignoring routine maintenance can escalate minor issues into major problems, causing unexpected downtime.

Solution: Implement a preventative maintenance program, including lubrication, belt alignment checks, and component replacements.

8. Electrical Hazards

Risk: Faulty wiring or damaged electrical components pose a risk of fire or electrocution.

Solution: Conduct regular electrical inspections and address any issues immediately.

9. Environmental Factors

Risk: Dust, moisture, and extreme temperatures can impact conveyor system performance and longevity.

Solution: Use systems designed to withstand specific environmental conditions and ensure regular cleaning.

10. Legal and Liability Issues

Risk: Accidents resulting from faulty or poorly maintained conveyor systems can lead to lawsuits and financial penalties.

Solution: Collaborate with a conveyor expert witness to evaluate potential liability risks and establish robust safety protocols.

Preventative Strategies for Conveyor Systems

To avoid these risks, organizations should:

- Conduct regular safety audits.

- Keep detailed maintenance records.

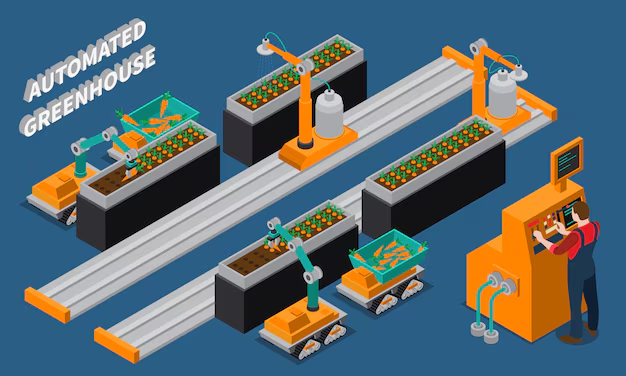

- Use modern technologies like sensors and automation to monitor system performance.

By addressing these risks proactively, businesses can not only ensure operational efficiency but also protect their employees and bottom line from avoidable hazards.