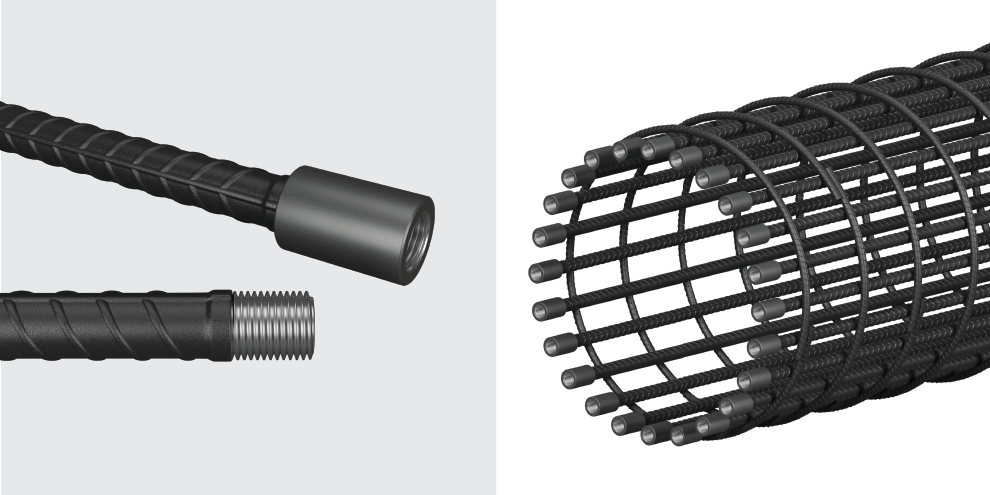

Rebar couplers are designed to provide a secure and reliable connection between reinforcing bars, transferring loads and stresses effectively. Numerous environmental factors and construction-related stresses affect the performance and durability of these couplers. Regular maintenance and care are necessary to identify and address any potential issues, ensuring the couplers continue to function optimally and maintain the structural integrity of the concrete.

Inspecting and cleaning rebar couplers

Visual inspections should identify any corrosion, deformation, or damage to the couplers. Corrosion weakens the coupler’s structural integrity, while deformation or damage may affect its ability to transfer loads effectively. During inspections, it is essential to clean the couplers thoroughly. Dirt, debris, and concrete residue accumulate within the coupler’s internal threads and grooves, potentially hindering its performance. Cleaning is done using a wire brush or a high-pressure washer, ensuring all surfaces are free from contaminants.

Lubrication and corrosion protection

Lubrication is a critical aspect of rebar coupler maintenance. The coupler’s internal threads and contact surfaces should be lubricated regularly to ensure smooth and efficient operation. Lubrication reduces friction, prevents galling, and facilitates easy assembly and disassembly of the coupler. To protect against corrosion, it is advisable to use corrosion-resistant materials or coatings for rebar couplers, especially in environments with high moisture or corrosive agents. Applying a suitable corrosion-inhibiting compound or paint provides an extra layer of protection, prolonging the coupler’s lifespan.

Proper handling and storage

The way rebar couplers are handled and stored can significantly impact their durability. Rough handling or improper storage can deform or damage the couplers. To avoid such problems, it is essential to follow the manufacturer’s guidelines. When not used, rebar couplers should be stored in a dry and protected area, away from direct sunlight and extreme temperatures. Proper storage ensures that the couplers retain their original shape and structural integrity, ready for installation when needed.

Regular maintenance schedule

Developing a regular maintenance schedule is crucial for effective Rebar coupler care. The frequency of maintenance will depend on various factors, including the environmental conditions, the type of project, and the specific coupler design. As a general guideline, visual inspections should be conducted regularly, such as every three to six months, or more frequently in harsher environments.

During maintenance, it is essential to document any findings, repairs, or replacements made. This documentation records the coupler’s history and helps identify recurring issues or trends. It also ensures that any necessary actions are taken promptly, maintaining the overall integrity of the reinforced concrete structure.

Rebar coupler replacement

Despite regular maintenance, rebar couplers may eventually end their service life and require replacement. Signs that a coupler needs replacement include severe corrosion, significant deformation, or structural damage that cannot be repaired. When replacing rebar couplers, it is crucial to use couplers of the exact specifications and quality as the original. Using inferior or incompatible couplers compromises the structural integrity of the concrete, leading to potential safety hazards. The proper care and maintenance of rebar couplers are critical to any concrete reinforcement project’s overall success and longevity.